heating elements, sensors, control & technical services

One of our biggest markets since founding is the South African plastics industry.

This industry has in the past faced severe challenges, emerging from a typically low efficiency industry and low investment to a more sophisticated industry using modern technologies, such as hotrunner systems, to remain competitive.

Our contribution to this industry has been a substantial one. We were founded in 1980, where we kick-started our production of heaters and sensors for the plastics industry. In 1990 we started producing micabands and manufacturing our own controllers.Shortly thereafter, we adopted the agencies for overseas brands Gefran, Hotset, Elstein, Thermoplay hotrunner systems.

In 2000 we broke into the export market with our sensors.

Heating, sensing & control systems for the plastics & packaging industry

Always maintaining our stance on quality; with careful selection of materials, special attention to detail, quality inspection and test before shipment – our products are designed to last longer and to reduce maintenance costs.

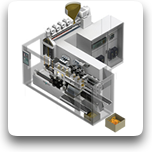

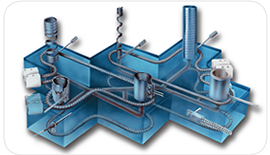

Heat-Cool Control Loop

Application example: Heating Elements + Control Components on Plastic Blow Moulding Machines

|

All parts in the control loop are essential and need to be selected, installed and set up correctly.

|

Catering for specialist plastics & packaging processes

Typical applications range from plastics injection moulding, plastic blow moulding, plastics extrusion, plastic vacuum & thermo forming to packaging processes, plastic fabrication and welding, heat shrinking, printing/ drying/ curing & more.

For more information on key applications and best suited product selections, please take a look at our applications tab.

Applications

Specialist solutions for plastics & packaging applications

Plastics Injection Moulding

Plastic Blow Moulding

Plastics Extrusion

Plastic vacuum & thermo-forming

Industrial Heaters

12 months warranty

Our warranty covers in-house manufactured unitemp mica and ceramic heater bands and includes any flat version of these elements. The warranty excludes brass and stainless steel nozzle elements.

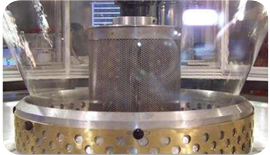

Hot Runner Systems for plastic injection moulding

Together with Thermoplay, we offer a wide range of hot runner components:

>400 types of nozzles,

> 80 standard manifolds,

flow analysis & control solutions, custom designed solutions,

bi-injection, multi-materials and sequential injection using pneumatic and hydraulic valves also for gas filled products. Contact us

Automation & Sensors

Our range of standard, locally manufactured temperature sensors includes numerous designs found on well-known brands of machines throughout the world (such as Arburg, Kawaguchi etc.).

The construction and materials have been carefully matched to satisfy the specific requirements of the plastics and packaging industries.

We can manufacture Custom Temperature Sensors such as mineral insulated thermocouples as small as 0.5mm in diameter and Pt100 sensors down to 1.6mm diameter.

Top Brands

Dedicated global brands with specialist industry focus

With established overseas brands in our portfolio, locally manufactured elements and temperature sensors, and a fast replacement service, we are in an ideal position to help the plastic industry remain competitive:

Heating Elements,

Temperature Sensors,

Industrial Supplies

Manufactured in South Africa,

our trusted in-house brand.

Our Team

Plastics & Packging: Our industrial specialists across sub Sharan Africa

CAPE TOWN SALES TEAM | |||

Craig Dullisear External Sales Send Email |  Johan Loubser External Sales Send Email |  Heinrich Dryling Internal Sales Send Email |  Toni Zeeman Internal Sales Send Email |

Fatiema Karriem Customer Service Consultant Send Email |  Yvette van der Merwe Customer Service Consultant Send Email |  Manfred Kriess Technical Specialist Send Email |  Werner Honing Project Engineer Send Email |

GAUTENG SALES TEAM | |||

Riaan Pretorius Sales Representative Send Email |  Michael Lottering Sales Representative Send Email |  Robert Hambly Project Manager Send Email |  Chris Naidoo Customer Service Consultant Send Email |

Janay Rabie Customer Service Supervisor Send Email | |||

TECHNICAL SUPPORT | |||

Brett Cottle Senior Technician - CT Send Email |  Mooketsi Lekoma Technician - CT Send Email |  Cyril Dlulisa Senior Technician - JHB Send Email |  Moloti Talane Technician - CT Send Email |

MANAGEMENT | |||

Andrew Semple Sales & Marketing Manager Send Email |  David Rogers Engineering Manager Send Email |  Tanja Chater Supply Chain Manager Send Email |  Ulf Hitzeroth Operations Manager Send Email |