Practical considerations for industrial applications:

For a physical variable that is being measured most often in industry, temperature is a surprisingly difficult parameter to measure with the precision that one might reasonably expect. To obtain accuracies better than 1.0°C certain attention to detail is needed. One must be able to identify exactly what is to be measured and the required accuracy. When we speak of sensors/ “thermometry”, we speak of

a) the sensor itself and

b) the instrument that takes the reading.

For the protocol here are 4 basic terms in measurement technology:

- Sensor: typically sensing device built into a protective sheath

- Sensor signal: the part which converts the physical value into an electrical signal.

- Probe: contains the sensor. There are different probe designs available for the various applications.

- Measuring instrument: the measuring instrument converts probe signals into display values.

Types of sensors

There are two sensor families:

- RTDs which change resistance in proportion to temperature, and

- Thermocouples made of 2 dissimilar metals and produce a millivolt signal in proportion to temperature.

Thermocouples can be made in small sizes and their measuring points are well defined (ie. good for surface measurements).

Generally, RTD’s are not as compact as thermocouples, are less suitable for surface measurements, but ideal for when accuracy is critical.

Choosing the right sensor

Different industries have different requirements. Specific measuring instruments are also suited to specific applications.

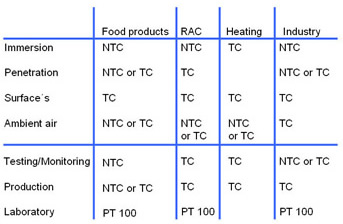

Figure 1: Selecting the right temperature sensor for various applications in different industries

The selection of the suitable temperature sensor is carried out according to the following criteria:

- measuring range

- accuracy

- response time

- resistance

- design

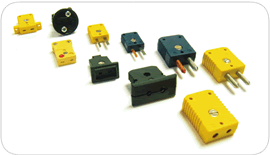

International Colour Codes for Thermocouples

There always seems to be a trade-off involved when selecting the right sensor:

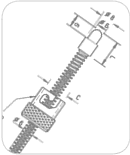

- Accuracy is largely dependant on how well the sensing device picks up the temperature from the substance.

Good heat transfer is therefore imperative and depends on the construction of the sensor. - Small contact area between sensor and target coupled with a thick-walled protective sheath leads to inaccurate measurement and a slow response time. However, this is sometimes required , e.g. sensing of viscous fluids which are in flow or of highly turbulent gases requires mechanical strength (a thick and strong protective sheath).

- A deep insertion depth gives more accurate readings but the required long sensor stem tends to oscillate, leading to pre-mature failure.

The right choice of temperature sensor for your industrial applications

Take the right choice to optimise your temperature measurement results! For a selection of our standard- and custom-made temperature sensors, please visit our product catalogue or contact us to discuss your requirements.