The problem often encountered in plastic processing factories is the pressure build-up on extruders. It is, therefore, essential to monitor pressure build-up in order to ensure plant safety. Mercury sensors cannot be used to do so, as this hazardous substance can contaminate any production coming into contact with food, such as containers, bottles, caps, bags and wrapping materials.

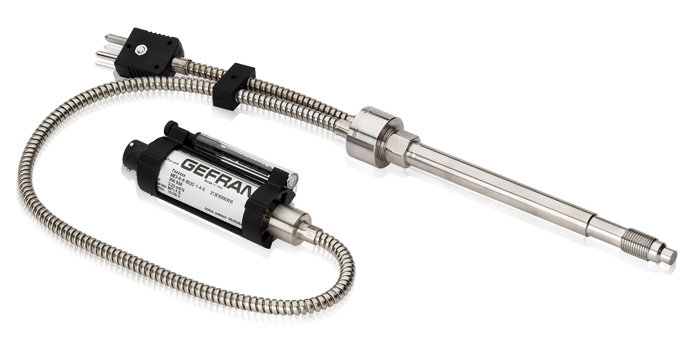

unitemp has the solution: Gefran's new mercury-free melt pressure sensors. The unique aspect of this new range is that the sensors are made of an FDA-approved oil fluid filling.

These mercury-free sensors can monitor pressure build-up at high temperatures - up to 400°C - without the risk of contamination.

All of Gefran's new melt pressure sensors are stainless steel, come in various configurations, offer high resistance to abrasion and are fully interchangeable with other brands.

unitemp now also supplies Gefran's NaK sensors composed of sodium and potassium, a non-toxic liquid metal that safeguards the environment even when working at extreme temperatures, as well as fluid-free sensors.

Published in 2007, March, in Instrumentation & Control